SPARKLING WINES

The production of base wines follows a clear production process that starts from the harvest and ends with bottling.

But there is a substantial difference between the approach that guides the production of still wines and that of sparkling wines: in the first case, once the objective to be achieved has been established, the path is built starting from the grape and moving towards the bottle; in the case of sparkling wines, however, once the desired product has been identified, the path is reversed and envisages the choice of the most suitable grape as the last point.

The most important parameters to consider in order to carry out a good pressing are:

- the threshold pressure for breaking the grape;

- the state of turgidity of the grape;

- the homogeneity of ripeness;

- the thickness of the peel.

Proper management of the must and of the pressing are the keystones for obtaining a good sparkling wine.

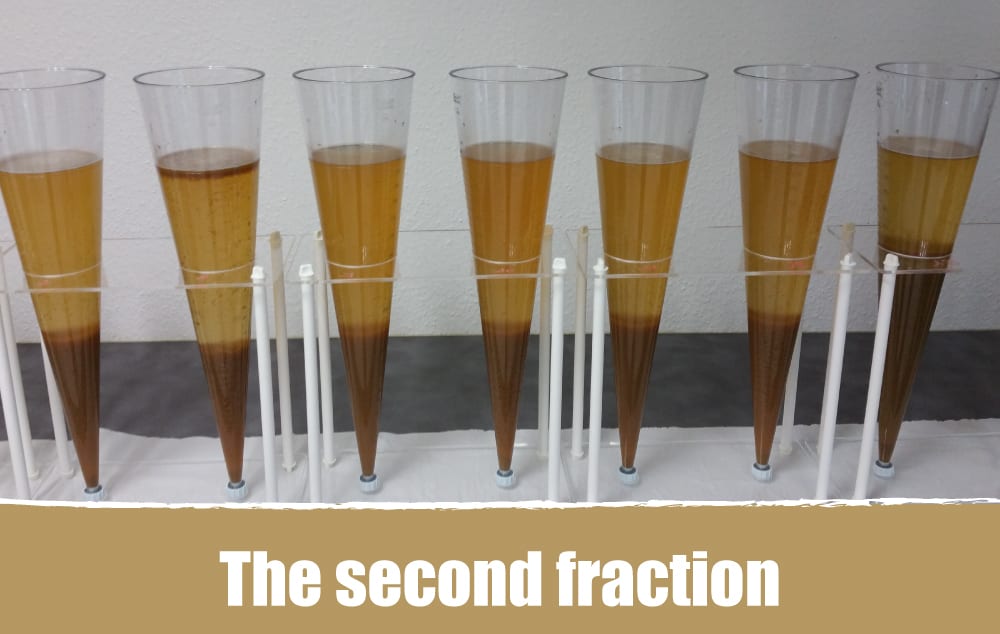

By fractioning the juice we can intervene in a targeted manner in order to optimise every single fraction, each with a different quality: the drained must, the free-run must, the second fraction and the marc.

The drained must, defined as "the must for washing the peel", can be rich in residues of plant-protection products, copper, yeasts and indigenous bacteria. As it is not suitable for bottle fermentation (prise de mousse), it must be processed separately in order to evaluate its use. Cleaning must be carried out on this type of must, aimed at eliminating all residues of plant-protection products, plant-based and polyphenolic notes. We therefore recommend using enzymes and clarifiers with a broad spectrum of action, including plant-based, vegan and allergen-free clarifiers.

The free-run must, also known as first fraction, is the most valuable part of the grape; and is characterised by high acidity and a low polyphenolic charge. It represents about 40-50% of the weight of the whole bunch, and, if well processed, requires only the addition of enzymes which respect the protein charge of the must to preserve its natural potential for bottle fermentation (prise de mousse).

The second fraction fraction of the must comes from the most external and aromatic part of the grape, located between the mesocarp and the endocarp: this contains some polyphenols and there is a higher pH than in the free-run must. On the second fraction it is a good rule to use targeted clarifying agents in order to ensure the elimination of oxidizable polyphenols.

The marc represents the must subjected to the highest pressure, it has a polyphenolic charge higher than that of other musts and is also more oxidised. The presence of potassium is high, and the acidity is low. We recommend the use of clarifying agents with a broad range of action on this must to eliminate oxidizable and oxidized polyphenols.

OUR COMMITMENT

FOR A TARGETED AND SUSTAINABLE OENOLOGY

Obtaining clean musts is the basis for producing a good sparkling wine: by taking into consideration the chemical-physical characteristics of the musts, over time our team of experts has managed to perfect clarifications aimed at reducing the quantity of solid particles and at improving their organoleptic characteristics.

Ours is a modern approach to oenology aimed at the management and natural treatment of musts so as enhance the fruit of the vine, which man has always cultivated with great passion.

The range of products recommended on this page is indicative.

For more information, contact the branch or sales service of the country of reference.

CIDER

CIDER

United Kingdom

United Kingdom