Equipment

AEB is a leader in the design and production of technologies for the wine sector. Flexibility and customisation have always been our mission. Indeed, AEB's team of professionals and technicians is committed on a daily basis to creating customised equipment for wineries, aimed at achieving maximum results from the production process. AEB's unique offer consists of a complete range of wine-specific equipment designed for each process step, from vinification to bottling.

Filter

Filter

DOSING AND MIXING UNITS

DOSING AND MIXING UNITS

DOSAPROP

DOSING AND MIXING UNITS

Autoclave dosing unit

DOSING AND MIXING UNITS

DOSANOXIT T

DOSING AND MIXING UNITS

DOSAPROP FLUX SET

FLOATATION UNITS

FLOATATION UNITS

E-Flot

REHYDRATION

REHYDRATION

Reactivateur 60

VAT exclusive

REHYDRATION

REACTIVATEUR 60 RIF

STABILIZATION

STABILIZATION

Stabymatic

STABILIZATION

Ctrl-T

STABILIZATION

ISIOX

STABILIZATION

STABYMATIC 500 SINGLE-COLUMN (AUTOMATIC)

Fermentation management

Fermentation

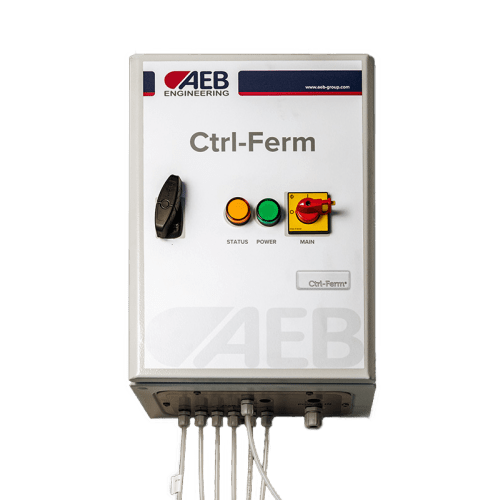

Ctrl-Ferm®

Fermentation

CTRL-TANK

LUBRICATION

LUBRICATION

Lubimatic

GENETIC ANALYSIS

GENETIC ANALYSIS

Icgene

Liquid handling

Liquid handling

SAFE AND AUTOMATIC PRODUCT UNLOAD SYSTEM

Micro-oxygenation

Micro-oxygenation

MICROSAFE O2

Micro-oxygenation

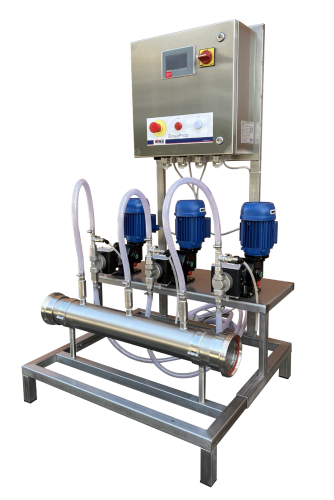

MICROSAFE X6

Infusion

Infusion

Boisélevage Extractor

MACERATION

MACERATION

RED FAST

AEB HARVEST EQUIPMENT

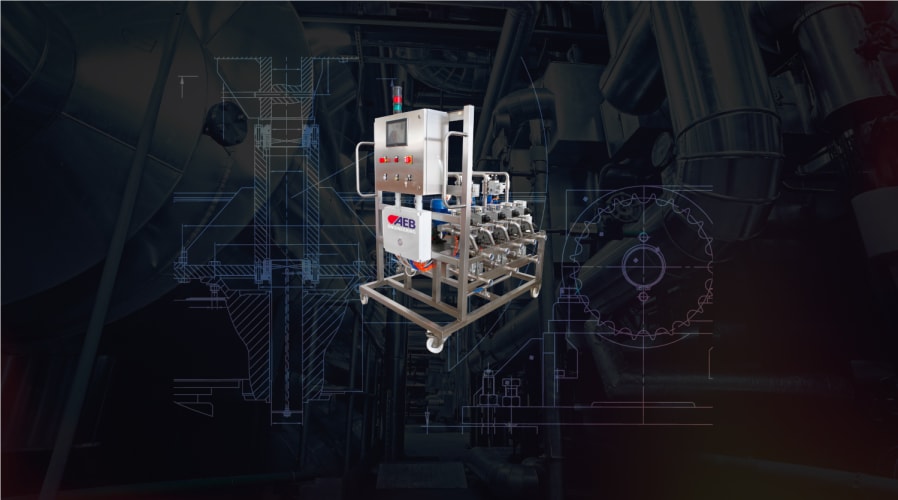

FERMENTATION MANAGEMENT

Reactivateur 60

VAT exclusive

DOSING AND MIXING UNITS

DOSANOXIT T

DOSING AND MIXING UNITS

DOSAPROP

DOSING AND MIXING UNITS

Autoclave dosing unit

MACERATION

RED FAST

FERMENTATION MANAGEMENT

CTRL-TANK

BOTTLING

BOTTLING

WINE RECOVERY SYSTEM

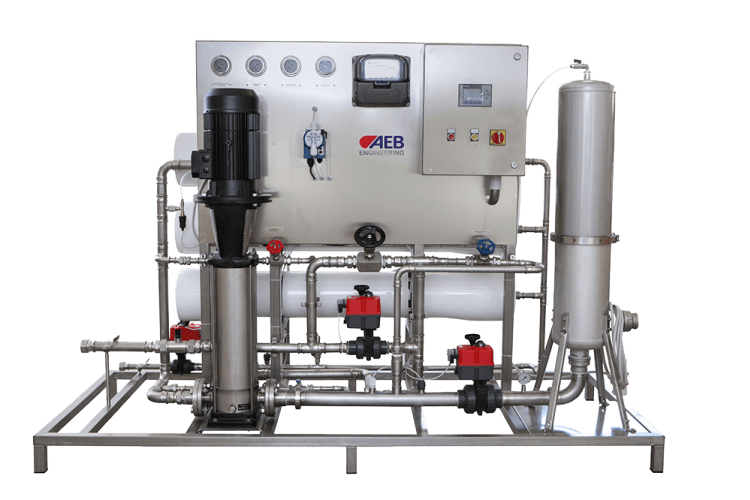

SYSTEMS AND EQUIPMENT FROM THE AEB RANGE DEDICATED TO OENOLOGY

The experience gained by our group in the development of plants and equipment dedicated to oenology allows us to propose ourselves as the ideal partner for high-tech plant solutions. The advantage of being a manufacturer and having a team specialised in the oenological sector allows our Group to design plants of different sizes and in line with customer requirements. The uniqueness of the proposal is guaranteed by the presence of AEB ENGINEERING and the constant presence of experts at the customer's service, ready to respond quickly to any request.

AEB ENGINEERING is the division of the AEB Group specialised in the design and production of systems aimed at satisfying any need during the entire production process: from grape harvesting to must clarification, from fermentation to tartaric stabilisation, from filtration to refinement, up to equipment cleaning and lubrication. The range includes equipment for dosing and yeast rehydration.

CIDER

CIDER