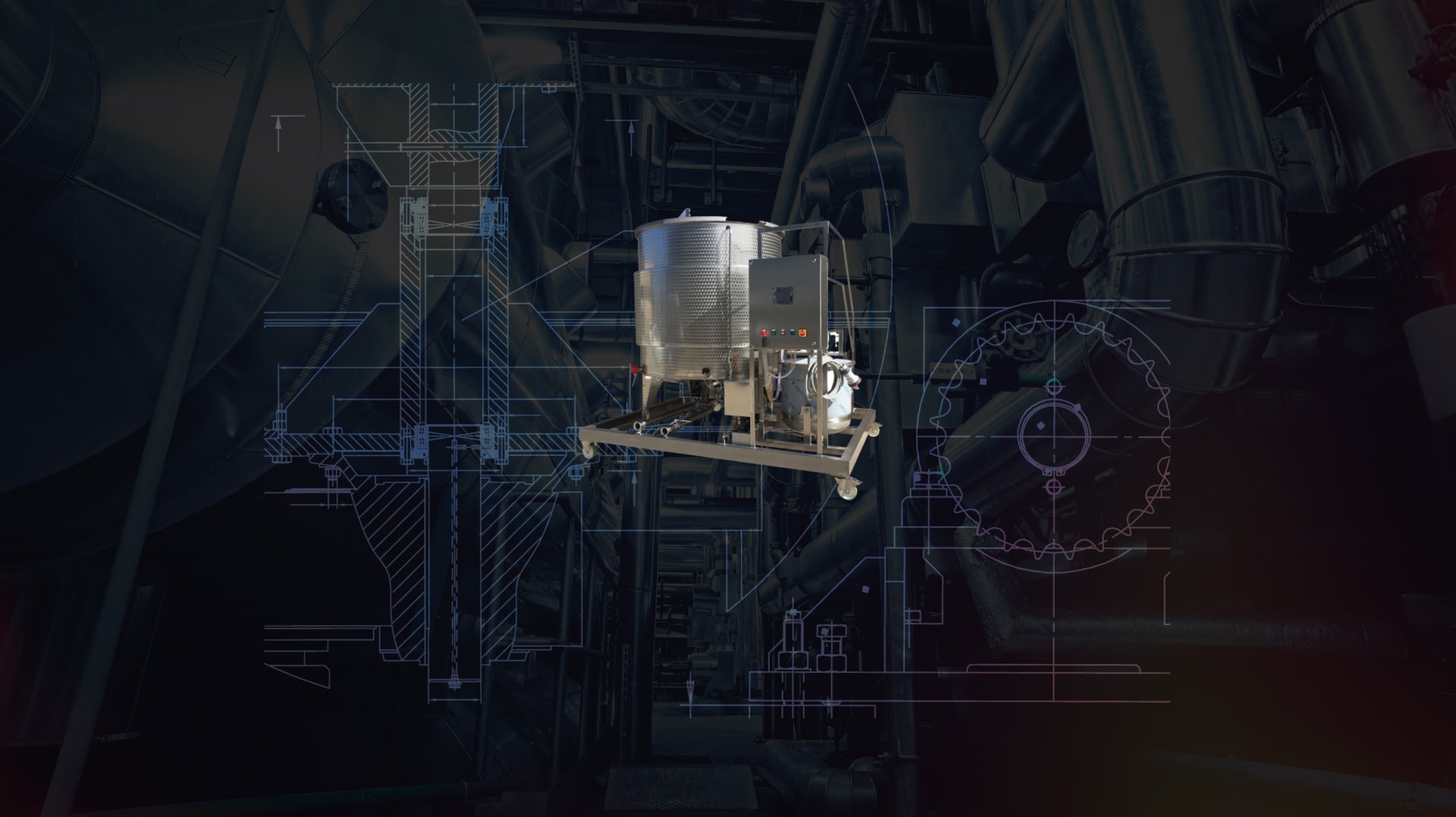

REACTIVATEUR 60 RIF

AUTOMATIC REACTIVATION AND ACCLIMATISATION SYSTEM OF YEASTS

Reactivateur 60 RIF automatically executes all the procedures required to prepare yeast for inoculation and ensures extremely consistent alcohol fermentation.

AEB ENGINEERING: GUARANTEED DOMINANCE DURING FERMENTATION

The Reactivateur 60 RIF system is manufactured by our AEB ENGINEERING division. Thanks to a production that is 100% in-house and on-site, we promise the highest quality and reliability of the technologies used. AEB ENGINEERING specializes in the manufacture of automatic systems for the rehydration and reactivation of yeasts during the fermentation processes, analysis equipment, systems for the processing and production of food, equipment for cleaning and sanitizing of any environment. AEB guarantees flexible and personalised support, both during installation and also after purchase.

BENEFITS

- Reduction in yeast latency times

- Extremely consistent alcohol fermentation

- Guaranteed fermentation dominance

- Better fermentation kinetics

- Certainty that the inoculated mass is active and at the highest multiplicative stage

- Reactivation of interrupted fermentation

- Possibility of producing must and yeast for re-fermentation with Charmat or Classic method

RANGE

The range includes a number of models.

-

MODEL

60/800

60/1200

60/2000

60/3000

QUANTITY OF YEAST (KG)UP TO 25

UP TO 25

UP TO 40

UP TO 50

RANGE

The range includes a number of models.

-

MODEL

60/800

60/1200

60/2000

60/3000

YEAST (KG)UP TO 25

UP TO 25

UP TO 40

UP TO 50

OPERATION

To reactivate the yeasts, two simple actions are enough: press the start button and the machine will let in the right amount of water, selected according to the quantity of yeast to be reactivated. It will then heat it to the set temperature (38°C).

An audible signal will alert the operator that they can add the yeast to begin the rehydration phase. The water and yeast will then undergo alternating phases of agitation, pause and aeration. Afterwards, the system will slowly add some must / wine / H2O / RCM based on the settings decided by the winemaker oenologist. The must can be added in two ways: according to time or temperature difference, whichever is reached first.

CIDER

CIDER

Argentina

Argentina

Brazil

Brazil

Chile

Chile

China

China

France

France

Hungary

Hungary

Portugal

Portugal

Spain

Spain

United Kingdom

United Kingdom