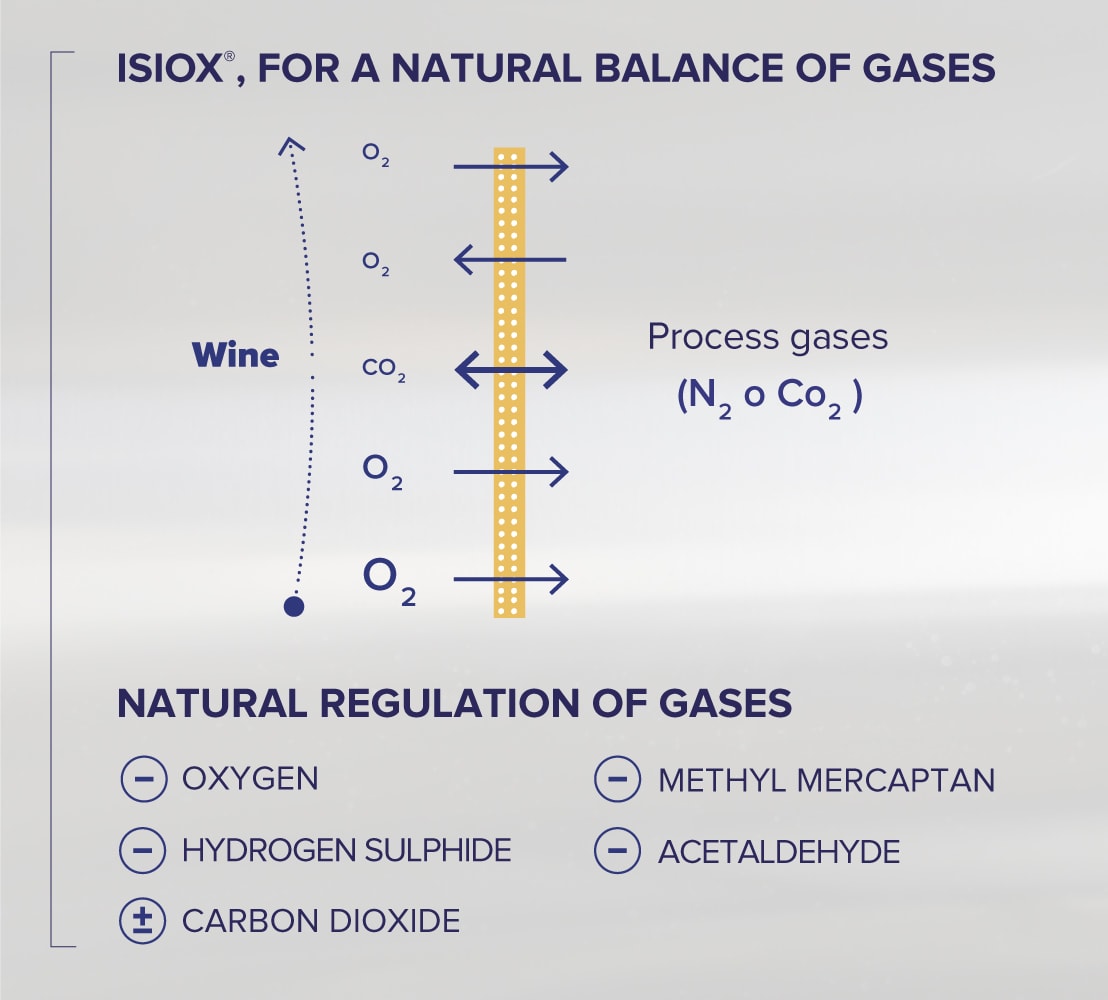

ISIOX®

SYSTEM FOR THE MANAGEMENT OF GASES DISSOLVED IN WINE

ISIOX is designed to optimize the various low molecular weight gases dissolved in wine in a simple, non-invasive way, with automatic and semi-automatic modes of operation.

It allows standardized results and bottle shelf life improvement.

FOCUS ON STABILIZATION

BENEFITS

- Processing of all types of wine

- Simple to use via user-friendly and intuitive interface

- Rapid integration into production lines

- Automatic and semi-automatic modes of operation

- Display of status parameters and alarms

- Reproducibility of the operating cycle and standardized results

- Automatic adjustments to flow rate fluctuations

- Castors for transportation

- Made in Italy equipment

RANGE

The range consists of several models.

-

MODEL

ISIOX 1 TECH

ISIOX 2 TECH

ISIOX 500 TECH

ISIOX 1 LOGIC

ISIOX 2 LOGIC

ISIOX 3 LOGIC

ISIOX 4 LOGIC

ISIOX 5 LOGIC

ISIOX 500 LOGIC

FLOW RATE MAX (hL/h)UP TO 60

UP TO 120

UP TO 500

UP TO 60

UP TO 120

UP TO 180

UP TO 240

UP TO 300

UP TO 500

* The LOGIC models provide for the measurement of dissolved oxygen and its automatic management. The automatic management of carbon dioxide, also for LOGIC models, is optional.

The range consists of several models.

-

MODEL

ISIOX 1 TECH

ISIOX 2 TECH

ISIOX 500 TECH

ISIOX 1 LOGIC

ISIOX 2 LOGIC

ISIOX 3 LOGIC

ISIOX 4 LOGIC

ISIOX 5 LOGIC

ISIOX 500 LOGIC

FLOW RATE MAX

(hL/h)UP TO 60

UP TO 120

UP TO 500

UP TO 60

UP TO 120

UP TO 180

UP TO 240

UP TO 300

UP TO 500

* The LOGIC models provide for the measurement of dissolved oxygen and its automatic management. The automatic management of carbon dioxide, also for LOGIC models, is optional.

APPLICATIONS

ISIOX PROVIDES HIGHEST STANDARDS OF SUSTAINABILITY

ISIOX PROVIDES HIGHEST STANDARDS OF SUSTAINABILITY

-

SOCIAL SUSTAINABILITY

Reduction in the use of sulphur dioxide to facilitate the production of healthy wines

ECONOMIC SUSTAINABILITYReplacement of the most time-consuming manual processes

Reduction in operation times via automation

Reduction in electricity consumption (200-400 watt/h)

Reduction in technical gas consumption (nitrogen) as compared to stripping

ENVIRONMENTAL SUSTAINABILITYReduction in water consumption

Long service life

Reduction in the need for spare parts and consequent disposal thereof

Storing a dry sieve with no need for chemical sanitisers

CIDER

CIDER

China

China

Hungary

Hungary

Italy

Italy

United Kingdom

United Kingdom

WRITE HERE

WRITE HERE