LUBIMATIC

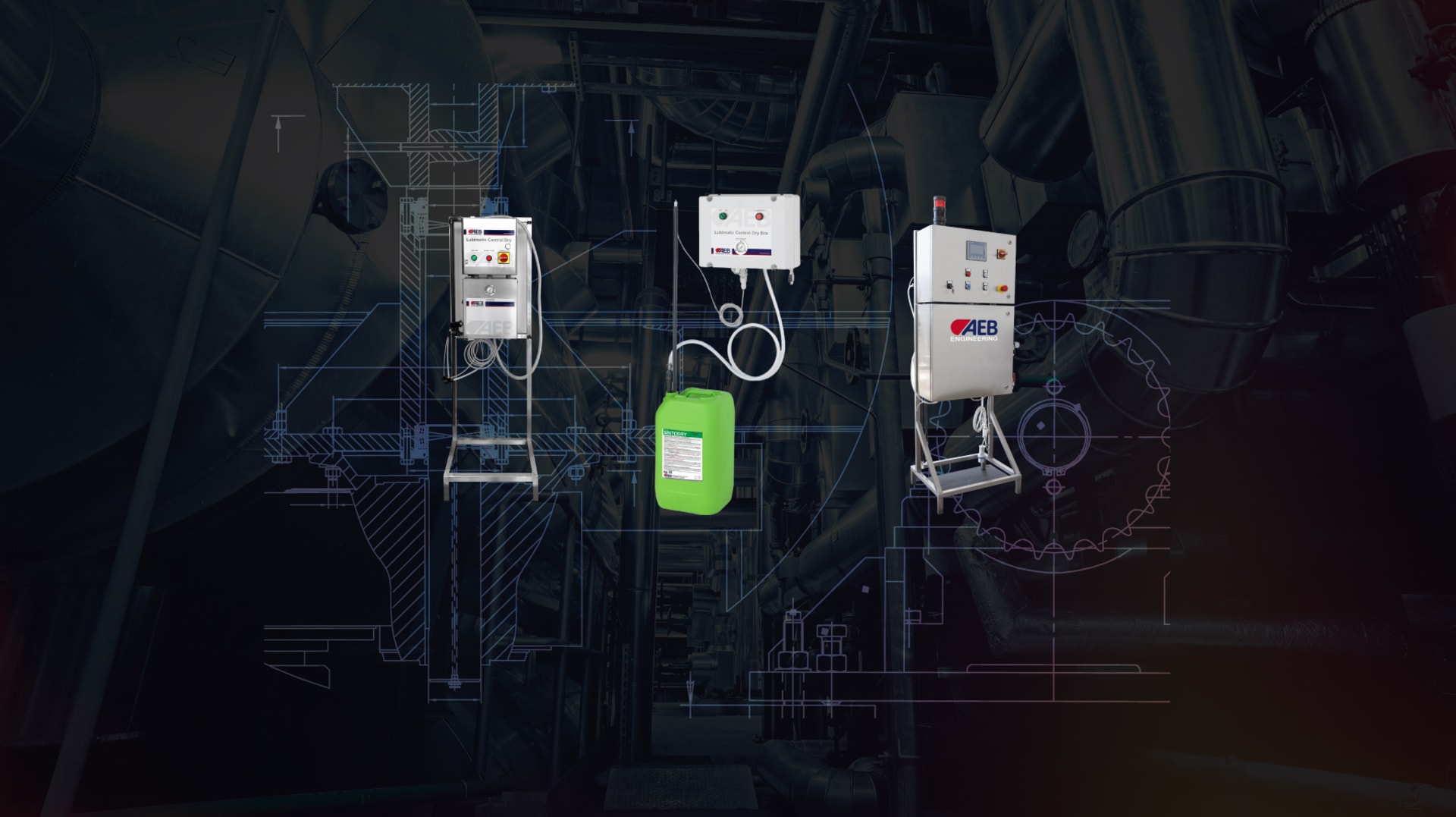

PLASTIC CONVEYOR BELT LUBRICATION SYSTEMS

The Lubimatic line consists of specially designed systems for the correct lubrication of conveyor belts, used in food industries for packaging liquid products, whether they are glass bottles, plastic containers, steel, aluminium or bonded materials. Keeping conveyor belts lubricated helps achieve many benefits, such as optimal stability of bottles and lower electricity and water consumption.

The pneumatic-style spray system, which characterises the Lubimatic models, is an innovative type of distribution and supply of the lubricant.

MAXIMUM EFFICIENCY AND SAFETY WITH AEB ENGINEERING TECHNOLOGIES

Just like all our equipment, Lubimatic systems are made by our AEB ENGINEERING division which, thanks to 100% in-house and on-site production, guarantees the highest quality and reliability for AEB technologies. AEB ENGINEERING is unique in that it provides constant support from our technicians, both during installation and after-sales. For an unparalleled service that is flexible and tailored to the customer needs.

THE IMPORTANCE OF CORRECT LUBRICATION OF CONVEYOR BELTS

At most Food & Beverage sector companies, the packaging phase is done on conveyor belts consisting of a series of meshes made from plastic or metal, connected by joints that allow them to be flexible and slide along runners, which are now almost exclusively made from plastic.

It has been shown that a lack of lubrication on conveyor belts has a definite effect on a companies’ energy efficiency, which, on average, accounts for 2%* of a company’s operating costs and potentialy 28%* in the event of poor lubrication.

It is therefore essential to lubricate conveyor belts properly because, alongside reducing electricity consumption, it ensures greater stability for containers on the conveyor belt and even greater accuracy and speed for the calibration of the doses.

* The costs indicated above refer to the use of “second-generation” lubricants (made from amines).

BENEFITS

- Optimal stability of the containers on the conveyor belt

- Extreme flexibility, accuracy and speed of calibration of the doses

- Increased safety for operators

- No microbial contamination

- Quick and easy washing of the conveyor belts

RANGE

Three Lubimatic models are available.

-

MODEL

LUBIMATIC CONTROL DRY 5 ZONE

TYPE OF

LUBRICATIONDry

MANAGEABLE SYSTEMS

Large systems (up to 80 lubrication stations)

DIMENSIONS HXLXD (CM)

155X50X36

LUBIMATIC CONTROL DRY ECO*

Dry

Small systems (up to 15 lubrication stations)

30X39X20

LUBIMATIC MULTI FU

Dilution

Large systems (up to 80 lubrication stations)

200X60X50

*The ECO version is fitted with just one area and can handle up to a maximum of 15 stations thanks to a timer for managing processing and break times.

RANGE

Three Lubimatic models are available.

-

LUBIMATIC CONTROL DRY 5 ZONE

TYPE OF LUBRICATIONDry

MANAGEABLE SYSTEMSLarge systems (up to 80 lubrication stations)

DIMENSIONS HXLXD (CM)155X50X36

-

LUBIMATIC CONTROL DRY ECO*

TYPE OF LUBRICATIONDry

MANAGEABLE SYSTEMSSmall systems (up to 15 lubrication stations)

DIMENSIONS HXLXD (CM)30X39X20

-

LUBIMATIC MULTI FU

TYPE OF LUBRICATIONDilution

MANAGEABLE SYSTEMSLarge systems (up to 80 lubrication stations)

DIMENSIONS HXLXD (CM)200X60X50

*The ECO version is fitted with just one area and can handle up to a maximum of 15 stations thanks to a timer for managing processing and break times.

MAIN COMPONENTS

The Lubimatic line systems are formed of:

- An electric switchboard, fitted with a PLC to manage processing and break times in each area, as well as a master control switch, an alarm and reset button, a test button and a line warning light, and an alarm siren if there is no air or product.

- A pneumatic circuit, formed of a pneumatic pump, a product suction line with a warning if there is no product, a reducing filter and solenoid valves to manage the supply of the lubricant.

- Utilities, or inputs and outputs for the air, the suction and the output for the lubricant, the earth 3P+ plug (for Control Dry models) and the earth 2P+ plug (for the Multi FU).

The control unit is combined with anti-drip pneumatic lubrication stations with a standard flow rate of 200 cc/min for the Lubimatic Control Dry and 130 cc/min for the Lubimatic Multi FU. With the Lubimatic Multi FU, you can also create a log of the formats used with automatic pairing of the supply/break times for each area.

CIDER

CIDER

China

China

Germany

Germany

United Kingdom

United Kingdom