Fermentation management

Each of our systems is manufactured by our AEB ENGINEERING division, which, thanks to 100% in-house and on-site production, guarantees the highest quality and reliability of AEB technologies. Thanks to its know-how, AEB ENGINEERING has created systems capable of responding to the need to optimally manage alcoholic fermentation, guaranteeing the desired technical and qualitative result.

Filter

Filter

SYSTEMS DESIGNED TO MONITOR AND MANAGE THE FERMENTATION PROCESS

The alcoholic fermentation of musts is a complex process that requires careful and calibrated yeast nutrition. Vintage, terroir, cultivar, LSA kinetics and winemaking technology influence the nutritional requirements of the yeasts, with the risk of slow fermentations, stuck fermentations or the appearance of unpleasant odours. Furthermore, errors in must sulphiting or poor management of O2 inputs in the initial stages of fermentation can compromise the final product. It is therefore essential for wineries to monitor the course of alcoholic fermentation and to be able to manage all interventions and additions of products such as activators, nutrients, clarifiers, etc. in a simple and automatic way. To respond to these needs, the AEB ENGINEERING division has developed systems and equipment capable of responding to the need to optimally manage alcoholic fermentation, guaranteeing the desired technical and qualitative result.

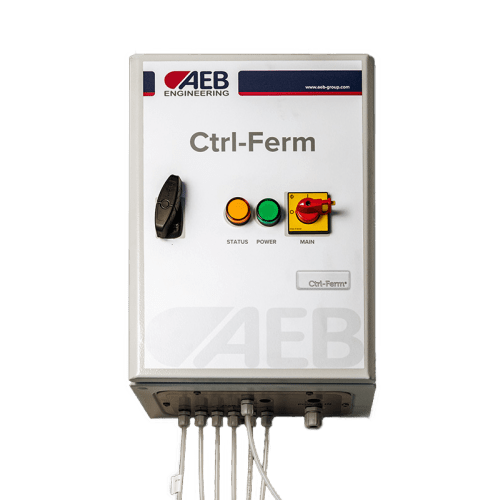

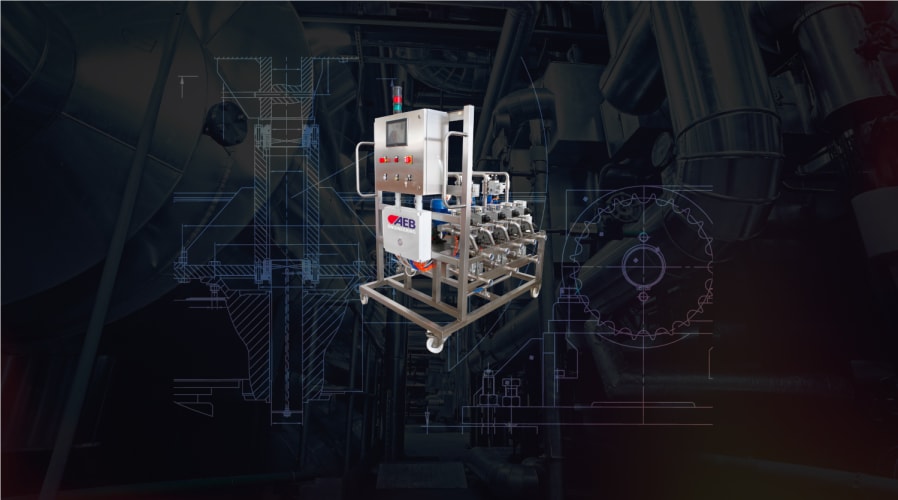

Preventive and simultaneous control of CO2 and H2S production is possible with Ctrl-Ferm, our group's patented system for measuring and monitoring the fermentation process. In order to allow precise dosing, we propose CTRL-TANK, equipment capable of dosing up to 3 different products simultaneously and/or separately in 5 tanks in manual or automatic mode with the possibility of programming additions over time, all of which can also be managed remotely.

The advantages offered by these instruments are many: accurate measurement of the quantity of CO2 and H2S; remote process control; easy and quick installation; an indispensable tool to guide the winemaker towards the right nutrition choices; programmable dosage execution; dosage precision thanks to product flow measurement; calibrated injection speed to avoid foam formation. Furthermore, the uniqueness of AEB ENGINEERING's equipment lies in the constant support of our technicians, both during installation and after sales. For unparalleled service, flexible and customised to the customer's needs.

CIDER

CIDER

United Kingdom

United Kingdom