-

AEB

- AEB

-

About

- About

-

Group

- Group

-

Info & Contacts

- Info & Contacts

-

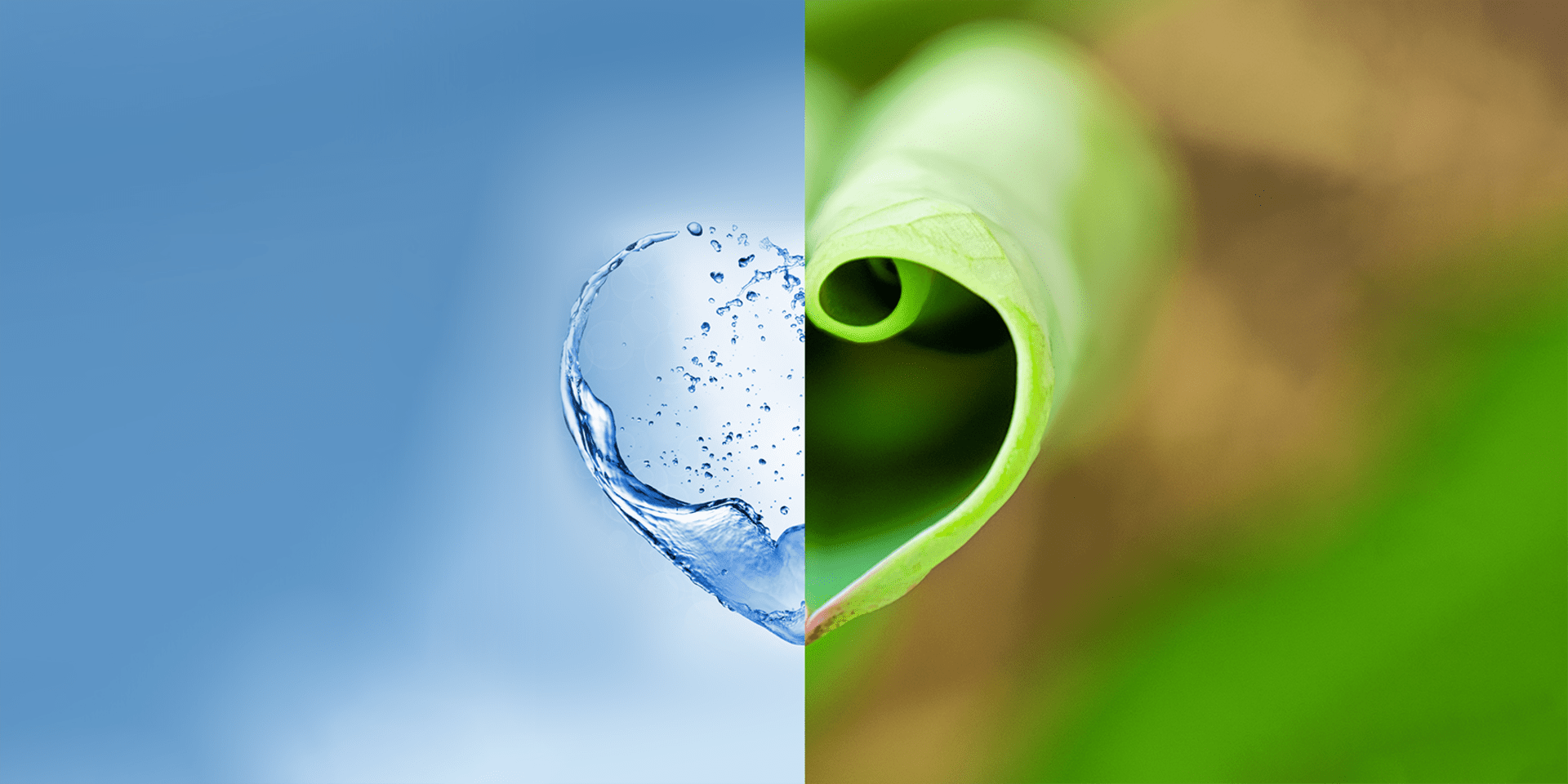

Sustainability

- Sustainability

-

OENOLOGY

- OENOLOGY

-

- Biotechnology

-

- Sanitation

-

- Equipment

-

- Filtration

-

BEER

- BEER

-

- Biotechnology

-

- Sanitation

-

- Equipment

-

- Filtration

-

- AEB Brewing lifesyle

-

FOOD

- FOOD

-

- Biotechnology

-

- Sanitation

-

- Equipment

-

- Filtration

-

NEXT

- NEXT

-

- HARD SELTZER

-

- DEALCOLIZED WINE

-

- CIDER

-

CIDER

CIDER

-

Discover AEB Cider

Discover AEB Cider

-

- Cider range

-

-

Sustainability

- Sustainability

CIDER

CIDER

Argentina

Argentina

Australia

Australia

Brazil

Brazil

Chile

Chile

China

China

France

France

Germany

Germany

Hungary

Hungary

Portugal

Portugal

South Africa

South Africa

Spain

Spain

United Kingdom

United Kingdom

USA

USA