How to filter wine

In oenology, filtration serves to clarify wines and eliminate micro-organisms. The aim is to achieve the clarity necessary to market the wine and, at the same time, stabilise it from a microbiological point of view.

When vinification is completed, the wine is in fact turbid: in suspension it has many particles from the original grapes and the micro-organisms used in fermentation. The first racking removes the larger particles, but the wine then undergoes further chemical and microbiological changes that make it cloudy again (or further).

Since one of the main characteristics that wine must have is clearness, it must therefore be clarified and stabilised before being placed on the market, so that it remains clear until consumption.

What is needed to filter wine

A physical-mechanical operation for the clarification and microbiological stability of wine, filtration can be carried out through different porous media that differ in terms of:

The main wine filtration techniques used today are: continuous filtration, deep filtration on cartons or filter sheets, cross-flow filtration and micro-filtration on membranes.

Continuous filtration

Continuous filtration involves the use of a filter medium with large pores, the size of which is reduced by depositing filtration aids on the filter, i.e. a bonding substance (typically cellulose and silicates).

Deep filtration on cartons or filter sheets

Deep filtration is also possible through the use of lenticular modules, which offer a complete and hermetically sealed solution to filtration through filter layers.

Cross-flow filtration

A technique developed in the 1980s, cross-flow filtration is the most advanced filtration method available. And it is constantly evolving, as organic and inorganic membranes are continuously being tested. Its advantage? It allows the wine to be clarified and stabilised by keeping it that way until it is bottled, reducing the number of steps needed to clarify it. This is due to the liquid flowing parallel to the filtering surface: in this way, the deposit of particles on the membrane is reduced to a minimum.

Membrane micro-filtration

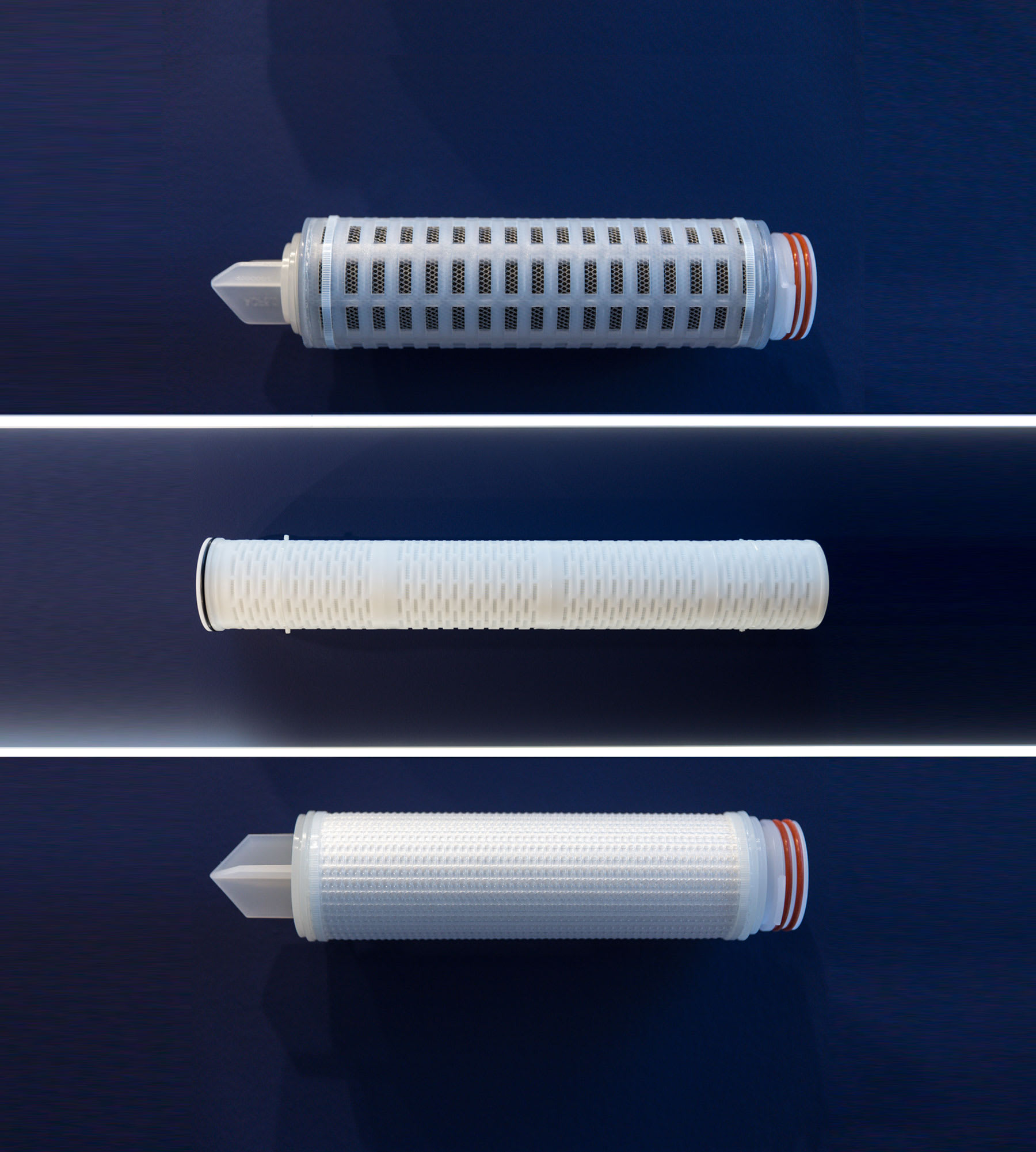

Membrane micro-filtration consists of separating fluids by means of a selective barrier (the membrane, in fact). There are many types of membranes available and they all rest on a pressure-resistant, macroporous steel or plastic structure. Since the liquid flows frontally with a consequent risk of clogging, membrane micro-filtration is generally preceded by pre-filtration steps.

Organic and inorganic membranes

Organic membranes are polymeric membranes, made from plastics and synthetic fibres. The most common are PES, resistant to PH variations and high temperatures, but unsuitable for high pressures and the use of cleaning solvents, and PVDF, suitable for food contact and highly resistant to heat.

When filtering wine

Wines are filtered before being bottled. Filtration may therefore concern young wines as well as aged wines, and involves the choice of a filtration medium consistent with the previous stages (racking, centrifugation, clarification).

However, filtration may also be carried out during certain intermediate stages of vinification, as required for sparkling wines, sparkling wines and still wines with natural residual sugar.

CIDER

CIDER

Argentina

Argentina

Brazil

Brazil

Chile

Chile

China

China

France

France

Germany

Germany

Hungary

Hungary

Portugal

Portugal

Spain

Spain

United Kingdom

United Kingdom