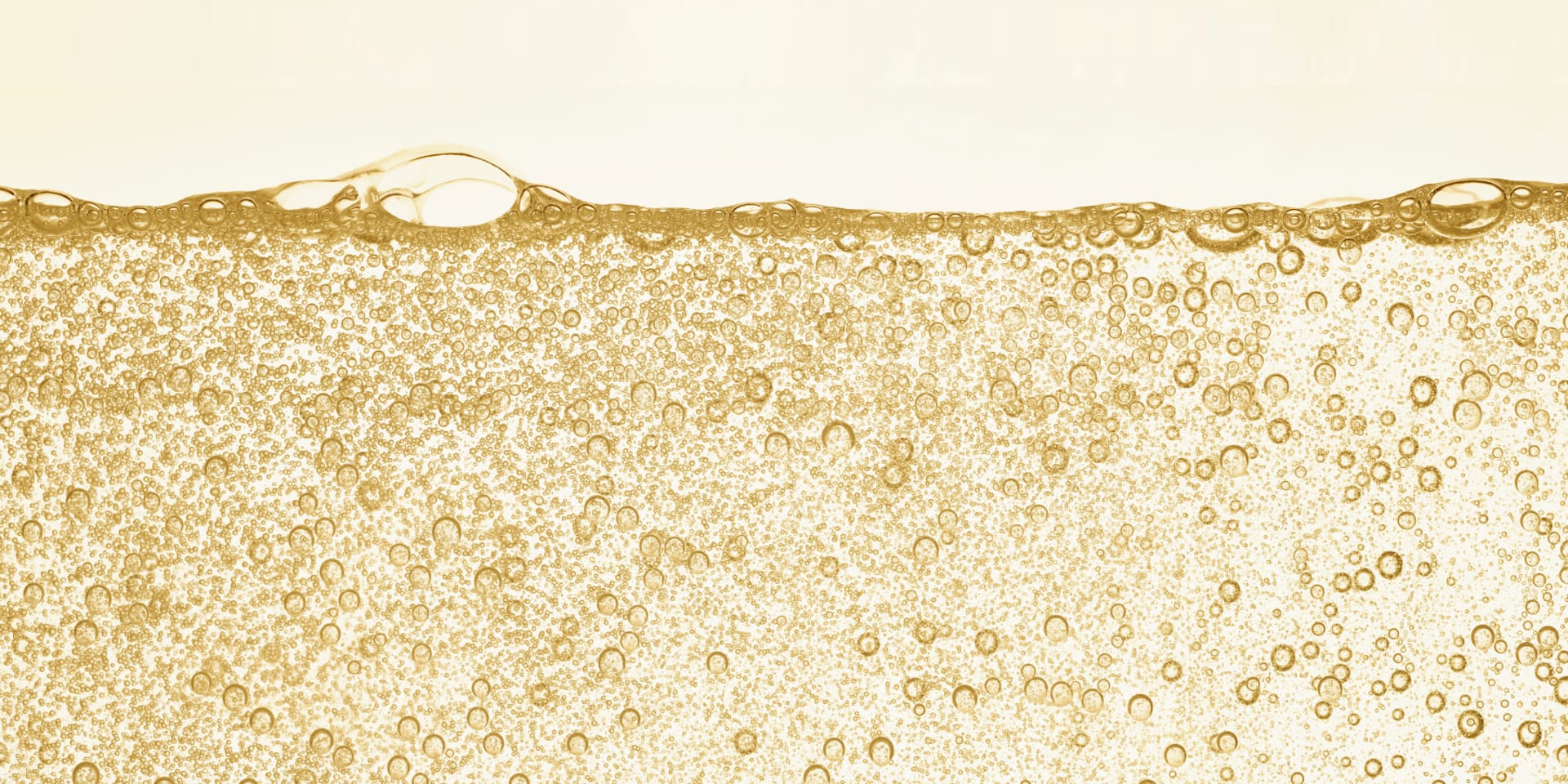

How sparkling wine works

As the name itself suggests, sparkling wine is the process that gives rise to sparkling wine from a still wine or from a blend of wines that differ in vintages and years.

What characterises sparkling wine is the presence of froth, originating from the carbon dioxide that develops as a result of fermentation. For it to be defined as sparkling, the wine must have a minimum pressure of 3.5 bar at 20°C.

Wine sparkling methods

Sparkling wine is usually made according to the Classical Method (or Champenoise) with re-fermentation in the bottle, or according to the Charmat Method, also known as 'Martinotti', with re-fermentation in an autoclave. Then there is a third way, the traditional yeast method, with natural re-fermentation in the bottle. In this case, the sugar solution proper to the sparkling process is not added, but the residual sugar with which the wine was bottled is re-fermented in the bottle with the yeasts from the first fermentation.

Classic Method or Champenoise

Sparkling wine making with the Classic Method originated in France, in the Champagne region (hence the name Champenoise). Towards the end of the 1600s, Pierre Pérignon, abbot of the monastery of Hautvillers, learned about the refermentation of wine in the bottle during a pilgrimage to Limoux (Languedoc-Roussillon). As to how sparkling wine came into being, to tell the truth, there is no certainty. Legend has it that some bottles of white wine exploded inside the monastery, suggesting to the abbot the presence of gas inside them. Other sources tell instead of the custom Dom Pérignon had of adding sugar to wines before bottling them, so as to make them more sparkling. What is certain is that it was he who realised the importance of a second fermentation. And who invented the Champagne production method, which, outside the area where it is produced, takes the name Metodo Classico.

In Italy, the Metodo Classico is used for the sparkling of non-aromatic wines. That is, of wines made from Chardonnay, Pinot Noir, Pinot Blanc or Pinot Meunier grapes. Or, for wines from indigenous grape varieties (always non-aromatic).

A solution consisting of base wine, sugar, yeast and mineral salts is added to the base wine or cuvée: this is the so-called 'liqueur de tirage', which allows the typical bubbles of sparkling wine (alcohol and carbon dioxide) to be obtained. The wine is then bottled: dark glass bottles are used, with a convex bottom and a crown cap with a small plastic cylinder, where the yeast will collect at the end of fermentation. The bottles are then placed horizontally in a dark place, at a temperature of 10-12°C, and remain there for at least 18 months (but the process can take years). Slowly, the yeasts transform the sugars, originating alcohol and carbon dioxide.

At the end of the long ageing process, the bottles are rotated (remuage) to separate the exhausted yeast from the sparkling wine: from the horizontal position, intermediate steps are taken until the bottle reaches the vertical position. This operation can be carried out by hand using special stands or mechanically using girapallets, capable of holding hundreds of bottles. The yeast lees, collected under the crown cap, must then be ejected: the bottle necks are placed in a refrigerating bath until they freeze so that, once the crown cap is opened, the plastic cylinder with the lees can be ejected.

Before the sparkling wine is finally bottled, liqueur d'expedition must be added to compensate for the dryness of the wine at the end of fermentation. The liqueur, depending on the sugar content, has its own dosage: if the same sparkling wine is used to top up, a dry sparkling wine (Brut Nature) will be obtained. But there are many possibilities: one can use barrel-aged wine, a distillate, cane sugar. The recipes are usually 'secret' and form the basis of unique and specific sparkling wines.

The last step of the Metodo Classico is the packaging. The bottles are corked with the final cork: some sparkling wines will be sold immediately, others will be refined further to obtain even more prestigious products. Standard sparkling wine should be consumed between 6 and 12 months from the uncorking date (shown on the label).

Charmat Method

The Charmat Method was invented in the late 19th century by Federico Martinotti (which is why it is also called the Martinotti Method). Reduced in cost and shorter in time, it sees the base wine fermented in temperature-controlled autoclaves. The name Charmat is a tribute to Eugène Charmat, who patented the method in the early 20th century.

This method of sparkling is perfect for wines from aromatic grape varieties, as aromas and flavours are extracted in less time than with the Metodo Classico and there is no long yeast residence time (which would spoil the aromas of the grape varieties).

All Stages of the Charmat Method

The cuvée of base wines is placed in an autoclave (a large stainless steel container, under pressure) for rapid fermentation. The duration of the process is 30-80 days, but it takes several months for the sparkling wine to stabilise for marketing.

The short timeframe makes it the most widely used method of sparkling wine production when large quantities of sparkling wine are required: from the double fermentation in an autoclave of refrigerated must comes the finished product, which has to be filtered and bottled.

As with the Metodo Classico, sugars, mineral salts and selected yeasts are added in the autoclave sparkling process. After mousse takes place, the wine is racked and filtered under isobaric conditions, then chilled, filtered, isobaric bottled and packaged. Many stages of the Charmat Method therefore take place under isobaric conditions, and thus under pressure, so that no carbon dioxide is released.

However, there is also the so-called 'Long Charmat Method', in which the wine remains with the yeasts for 9-15 months and often includes the addition of liqueur d'expédition: in this way, sparkling wines with a stronger aroma are obtained. Patented by oenologist Nereo Cavazzani in the 1970s, this method involves the use of propeller stirrers inside the autoclave to suspend fermentation sediments, giving a result similar to the Metodo Classico.

CIDER

CIDER

Argentina

Argentina

Brazil

Brazil

Chile

Chile

China

China

France

France

Germany

Germany

Hungary

Hungary

Portugal

Portugal

Spain

Spain

United Kingdom

United Kingdom